Remote Operating Capabilities In New ARO Controller Increase Reliability, Productivity And Safety Of Fluid Management

Automated Control System Supports Batching and Dispensing Operations

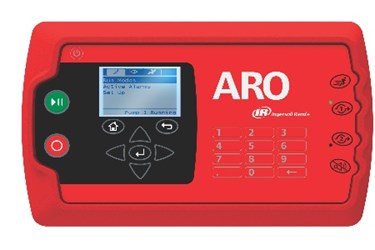

Ingersoll Rand, a global leader in compressed air systems and services, power tools and fluid and material handling equipment, delivers on the promise of touch-and-walk-away automation with the new ARO Controller. The Controller works seamlessly with ARO EXP Series Electronic Interface pumps and can be integrated with many existing ARO EXP pumps when an electronic interface package is added. The result is a fully automated, multi-pump system for batching and container and tank filling.

“ARO is proud to now offer a complete system solution that helps manufacturers and operators manage fluid easily and intelligently, with less operator oversight required,” says Nelson Wesley, global product leader for diaphragm pumps. “Less time standing at the pump means more time on the floor making sure things are running smoothly. The remote operating capabilities of the new ARO Controller help manufacturers increase productivity, reliability and safety.”

The ARO multi-pump Controller can be programmed with remote triggers customized to the application in which it’s being used. The Controller responds to those triggers, performing auto-shutdowns when necessary and sending data and service alerts to the operator. Based on that information, the operator is able to make intelligent fluid management decisions to keep business moving. For example, triggers can notify operators when it is time for predictive maintenance, when a leak has been identified, or when liquid levels are low − elements that work together to reduce downtime. Remote operation also allows for safer monitoring.

The ARO Controller improves upon the already precise ARO EXP pump by introducing a closed-loop system with proprietary logic to ensure the pump is fully primed. This results in a dispensing or batching system with plus or minus one percent repeatability. The Controller also features an easy-to-use interface that is pre-programmed with eight languages, supporting the needs of a diverse workforce and global operations.

The ARO Controller can also:

- Operate two pumps simultaneously, each with up to two batches.

- Detect leaks.

- Sense and respond to liquid levels.

- Accurately control proportions.

- Control flow-rates.

The system replaces the operator-intensive systems of the past and helps customers monitor their fluid management in a smart, straightforward way. Whether formulating ink, paint or chemicals, dispensing detergents or injecting chemicals, the ARO system provides precise results consistently.

The new ARO Controller will be available in November 2014 for order worldwide. For more information on the ARO Controller and intelligent fluid management solutions. For more information, visit AROzone.com.

About Ingersoll Rand

Ingersoll Rand advances the quality of life by creating comfortable, sustainable and efficient environments. Our people and our family of brands—including Club Car, Ingersoll Rand, Thermo King and Trane—work together to enhance the quality and comfort of air in homes and buildings; transport and protect food and perishables; and increase industrial productivity and efficiency. Ingersoll Rand products range from complete compressed air systems, tools and pumps to material and fluid handling systems. The diverse and innovative products, services and solutions enhance our customers' energy efficiency, productivity and operations. We are a $12B global business committed to a world of sustainable progress and enduring results. For more information, visit www.ingersollrand.com or www.ingersollrandproducts.com.

Source: Ingersoll Rand