Onsite Leachate Treatment Systems Reduce Cost And Environmental Risk

By Sara Arabi and Andrew Lugowski, Conestoga-Rovers and Associates

Traditionally, landfill leachate has been hauled or pumped to publicly owned treatment works (POTWs) or other off-site treatment facilities for disposal. Disposal of leachate to POTWs has generated opposition from the plant owners due to more stringent effluent discharge criteria, especially nutrients, as well as potential process upsets as a result of co-treatment of landfill leachate and municipal wastewater. Landfill leachates strongly quench UV light. When discharged to POTWs, leachates can interfere with UV disinfection. Leachate also contains heavy metals and high ammonia concentration which may be inhibitory to the biological processes at POTWs. The high refractory dissolved organic nitrogen (rDON) in the leachate may pose a problem for the POTW with stringent effluent total nitrogen (TN) discharge criteria.

Onsite leachate treatment is offered as an alternative to the increasing costs associated with hauling leachate to a local wastewater treatment plant. The onsite leachate treatment facilities are designed to fulfill the specific needs of individual landfill sites and allow landfills to treat their leachate and discharge effluent to sanitary sewer or water body without any hauling or disposal costs.

Two case examples of successful onsite leachate treatment facilities (LTFs) employing biological treatment processes (nitrification – denitrification) to remove nitrogen and organics from the leachate are presented. A combined biological and physical/chemical treatment was found to be highly efficient in removal of organics and inorganics components and offer an attractive alternative in dealing with the high variability of pollutant content in landfill leachate. Details of leachate characterization, pilot and bench scale studies, key design considerations, and lessons learned from designing and operating onsite leachate treatment systems are discussed.

CASE EXAMPLE 1- Green Lane LTF, St. Thomas, ON, Canada

Green Lane Landfill is located in St. Thomas, Ontario, Canada and was originally opened in 1978 for the disposal of local residential wastes. The 130-hectare site currently accepts domestic, commercial and solid non-hazardous industrial wastes from a province-wide service area. The site capacity is approximately 5.7 million tons, and approximately one-quarter of this capacity has been utilized to date. With current landfilling rates and air-space limitations, the remaining site life is estimated to be 20 years.

Extensive treatability studies were conducted prior to the design of the LTF including respirometry tests to determine the bio-kinetics, bench-scale coagulation/precipitation testing for colour removal. Coagulation and flocculation testing was conducted to compare alum and ferric chloride as coagulants with respect to the initial and final pH, dosage, sludge production, and extent of color reduction.

The bench scale treatability study proved to be useful in determining the feasibility of potential treatment processes for removing contaminants from the leachate. It also resulted in the collection of significant data for the full-scale onsite LTF design. The leachate was characterized by high COD (1,000 – 5,000 mg/L), ammonia (150 – 600 mg/L), TDS (2,000 – 6,000 mg/L), and intense colour (up to 1,200 Pt- Co).

A primary design criterion for the treatment plant was to incorporate significant flexibility in the treatment processes to allow for the expected variations in leachate quality and quantity throughout the landfill site life and beyond. In biological treatment systems, it is important to maintain a balance between the organic and nitrogen loads that result in a high nitrifier fraction in the biomass. Since nitrifiers have a relatively low cell yield, if there is a change in the available ammonia to biodegradable organic matter ratio, a shift in the biomass population can easily occur causing the nitrifier mass to be inadequate. The organics to-ammonia ratio in leachate varies significantly and this may cause poor performance in nitrifying system. Denitrification reduces the organic load to the aerobic nitrification tank which results in more stable nitrification. The most important factor in the sizing of the biological tanks is hydraulic retention time (HRT) and sludge age and the sizing of the tanks is a function of nitrification rates at the design temperature.

In order to reliably achieve the treatment required for the leachate with varying quality, the biological system was designed as Modified Ludzack-Ettinger (MLE) process for an extended retention time as indicated by overall HRT of 2 d (anoxic and aerobic HRTs of 8 and 40 hrs, respectively). Long HRT was found to be required for hydrolysis of slowly biodegradable compounds in the leachate and to achieve a low enough organics prior to aerobic nitrification.

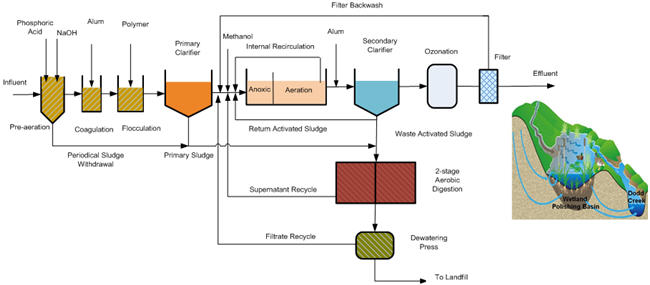

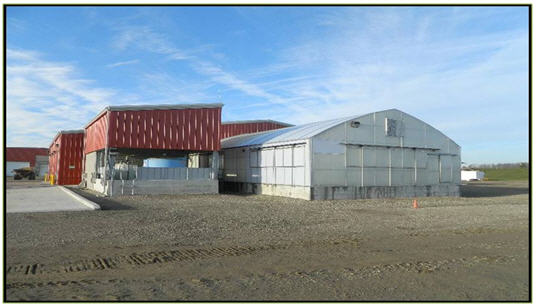

The schematic flow diagram of LTF is presented in Figure 1. The full-scale LTF designed at a capacity of 55 gallons per minute, includes pre-treatment comprising chemical addition and primary clarification to remove metals, hardness, and TDS, MLE process, followed by ozonation (to remove color) and filtration to treat leachate to acceptable regulatory levels for a surface water receiver. Phosphoric acid and methanol are added as supplemental phosphorus and carbon sources, respectively. The pre-treatment and biological tanks are housed in a building and greenhouse cover respectively, to eliminate cold winter temperature concerns (Photograph 1). The pre-treatment and biological tanks are presented in Photograph 2.

The 2008 -2013 average effluent concentrations are BOD < 5 mg/L, ammonia < 3 mg/L , and total phosphorus (TP) < 0.5 mg/L, which are all below the compliance criteria of 5 mg/L, 3 – 5 mg/L, and 0.5 mg/L, respectively. The average effluent total suspended solids (TSS) concentration ranged from 4 – 11 mg/L which is below the regulatory requirement of 15 mg/L. Long term consistent ammonia removal efficiency of 99% and COD removal efficiency of 60% - 80% were achieved. On average 70% - 90% color removal was achieved in the LTF. While there were no regulatory requirements for TN or nitrate, the LTF achieved on average 60-70% TN removal efficiency.

Figure 1. Green Lane LTF schematic flow

Photograph 1. Green Lane onsite LTF

Photograph 2. Green Lane LTF – Top: pretreatment tanks; Bottom: anoxic and aeration tanks

CASE EXAMPLE 2- McDougall Leachate Treatment Facility (LTF), Perry Sound, ON, Canada

The second case example is for a leachate from McDougall Landfill which has served as a solid non‑hazardous waste disposal facility since 1976. Groundwater studies at the landfill site indicated that residual leachate impacts resulting from the historic unlined landfill are present in the onsite groundwater regime. The contaminants of concern in groundwater were iron and manganese. The landfill owner decided to move forward with the design of a combined treatment facility to treat the impacted groundwater as well as leachate from ongoing landfilling activities.

Extensive bench scale treatability tests were performed on the leachate to identify processes suitable for reducing iron such as iron oxidation by aeration and by strong oxidants followed by precipitation. Biological process modeling was conducted prior to the conceptual design of the LTF. The treatability tests proved that iron oxidation by aeration is sufficient for the reduction of iron. Based on what had to be removed from the waste, it was determined that a chemical pre-treatment step is not required before the biological treatment.

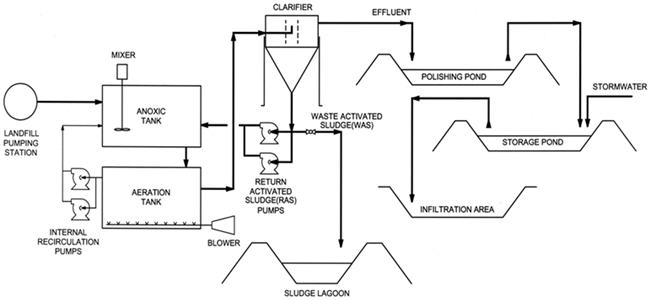

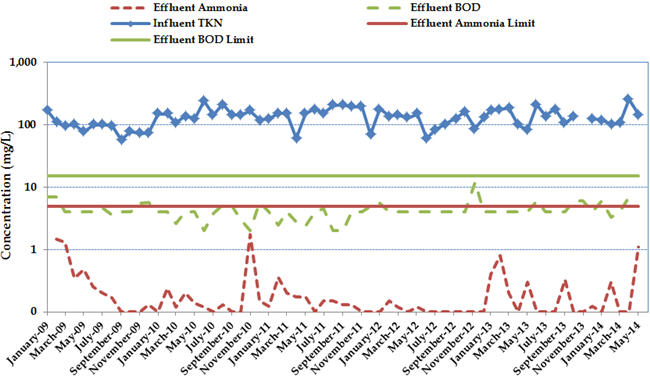

The impacted ground water and leachates are treated by a biological process designed to achieve nitrification and denitrification (Figure 2) at a design capacity of 24 gallons per minute. The major challenge in the design of this LTF was the high variability of influent TKN concentrations (60-250 mg/L), as depicted in Figure 3. In order to achieve stable operation in spite of highly variable carbon-to-nitrogen ratio, the overall LTF was designed for extended retention time of 2.3 d (anoxic and aerobic HRTs of 15 and 40 hrs, respectively). Methanol and phosphoric acid are added as carbon and phosphorus sources, respectively. The effluent from the clarifier is discharged to the polishing pond and a storm water/infiltration pond. A major concern in operating the biological systems in cold climates is the reduced nitrification performance or freezing during periods of low ambient temperatures. Due to the temperature considerations, the biological tanks are housed in a greenhouse cover.

Figure 3 plots the effluent ammonia and BOD concentrations from January 2009 to May 2014 and the respective compliance limits. Long term effluent quality averages are: ammonia of 0.1 - 2 mg/L, and BOD of < 7 mg/L which are lower than the respective effluent limits of 5 and 15 mg/L, respectively. The LTF achieved 99% ammonia removal for this period.

Effluent nitrate concentrations were in the range of 22 - 47 mg/L, reflecting excellent denitrification. Iron (and manganese in the impacted groundwater were reduced to Provincial Water Quality Objectives (0.3 mg/L iron) in the aeration system without pre-treatment.

Figure 2. McDougall LTF schematic flow diagram

Figure 3. McDougall LTF influent and effluent characteristics 2009-2012

Summary

Onsite leachate treatment systems are an attractive alternative to reduce the cost and environmental risk of hauling leachate to off-site treatment facilities or POTWs. With the new issues on the horizon with respect to landfill leachate disposal to POTWs such as UV transmittance inhibition, refractory dissolved organic nitrogen (r-DON), non-degradable COD, total dissolved solids/chlorides and emerging contaminants such as pharmaceutical and personal care products (PPCP), onsite leachate treatment systems are considered a viable option for many landfills.

Careful consideration is required for design of onsite LTFs for process selection in terms of technology capabilities as well as interrelationship with leachate characteristics and discharge options. Proper characterization of leachate, backed by treatability studies (bench tests or pilot studies) is essential to select a reliable LTF that can effectively accommodate variable influent characteristics.

Applicable technologies for onsite leachate treatment include a variety of physical/chemical processes as well as biological processes. The two case examples provided in this paper describe the suitability of biological processes for treatment of young and intermediate leachate. Nitrification and denitrification processes for biological treatment of leachate have been successfully implemented for removal of organics and nitrogen. The advantages of such processes include stable nitrification, higher degree of total nitrogen removal, reduction of oxygen demand, and lower sludge production rate. Provisions for addition of supplemental carbon source (such as MicroC™ Premium Carbon Sources or methanol) and phosphorus source may need to be included for treatment optimization.