Novel Technology Mimics Nature, Simplifies Biosolids Management

By Chip Bettle, Absolute Aeration, LLC

Every waste treatment system in the world has a biosolids management issue. For some it is just volume disposal; for others it is toxic disposal; for still others the issue is meeting the discharge requirements.

But what if all those problems just went away simply by cleverly stirring your sludge holding pond. After all, Nature has handled biosolids for millennia. It all starts with understanding how Nature does it and then mimicking her sustainable practices.

Nature has a 4-step biological process for recycling waste:

- Use oxygen to convert soluble substrate into insoluble biosolids and sink them.

- Hydrolyze sunk biosolids into simple soluble compounds

- Serially ferment simple soluble compounds into acetic acid

- Convert acetic acid into methane and carbon dioxide.

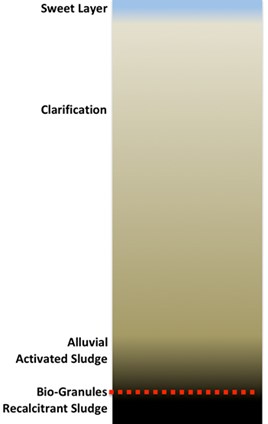

Nature does this by stratifying bodies of water. Aeration is at the top of the water column; methane generation is at the bottom. Nature does this by stratifying bodies of water. Aeration is at the top of the water column; methane generation is at the bottom.

Nature chose to protect the specialized anaerobic bacteria in a biofilm bonded to a heavy calcium carbonate granule. The granule weight keeps the obligate anaerobes at the bottom of the water column far away from toxic oxygen. There are 5 distinct layers:

|

Feeding granules is the key to digesting biosolids in situ.

The produced gas fluidizes the alluvial sludge, bringing small granules and substrate into intimate contact. The produced carbon dioxide is converted into local carbonate anion. The carbonate reacts with calcium that entered in the black water and the granules grow bigger. The methane escapes.

When the radial outflow from two adjacent 360° circulators impinge one on the other, equal and opposite flow vectors create a vertical hydraulic wall that transports surface substrate down to the hungry basement biofilm. Gas production increases.

Operators are also concerned with nuisance odors when digesting sludge. Nuisance odors have three sources:

- Raw biosolids have an unpleasant characteristic odor.

- This odor is mitigated by introducing raw biosolids below the capping sweet layer

- Volatile fatty acids (VFA) are an inherent intermediate in the 4step digestion process.

- VFA odors are not obvious if bacteria consume them as fast as they are produced

- Sulfur odors, primarily H2S, must be eliminated.

- Nature has a successful countermeasure to sulfur odors.

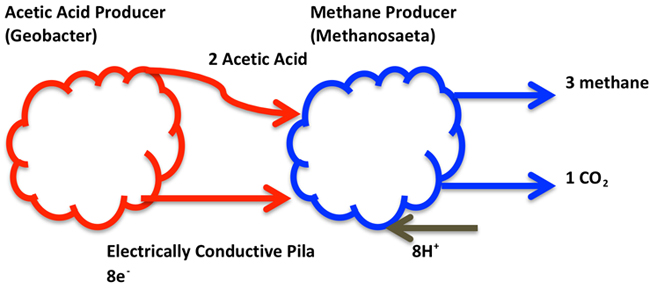

- On the bio-granule, the acetic acid producing bacteria is electrically plugged into a specialized methanogen (Methanosaeta). [See sketch.]

- The electrical "cord" (actually a pila) electrically "plugs into" Methanosaeta.

- Acid protons (H+) are consumed and the pH rises

- Electrons pass directly from Geobacter to Methanosaeta without making hydrogen gas.

- No H2; no H2S; no sulfur smell

- Nature has a successful countermeasure to sulfur odors.

There are several rules to digest biosolids in situ:

- Select for indigenous sludge digesting bacteria

- Discharge selected bacteria at the base of the water column.

- When the pH > 7.5 (once), the carbonate granules form in a high shear, aerated environment. Thereafter, acid consumption and local CO2 production makes carbonate anion in situ.

- Granules grow once initiated.

- Create hydraulic walls to bring sufficient substrate to the granules such that food transfer is not rate limiting.

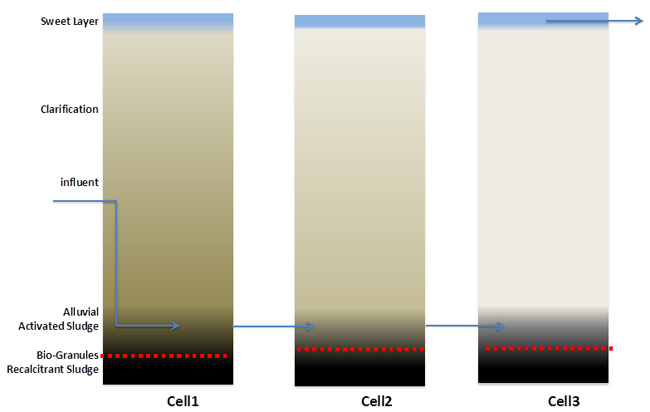

These rules are typically executed best in a multi-cell, engineered system

The inter-cell transfers occur low in the water column so that suspended solids enter in the fluidized bed of the downstream cell, not in the clarified supernatant. Your detention time is used for gas formation, not settling. The sweet layer is discharged from the final cell.

The Blue Frog System (BFS) is an engineered system that induces granule formation and then selects for sludge digesting bacteria. Bacteria and immature granules are discharged at the base of the water column. Once formed, the granules colonize the entire lagoon bottom and naturally regenerate themselves as acid is biologically consumed and local carbonate anions are produced.

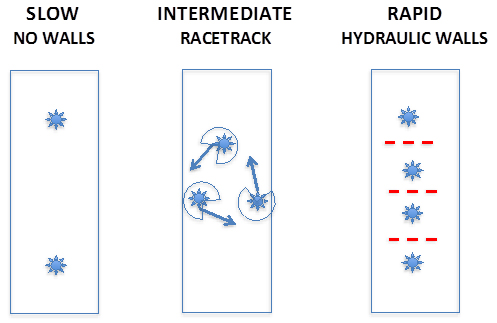

Modifying the circulation pattern downstream of the selector tank can vary the rate of sludge digestion:

- SLOW DIGESTION

- 360° surface circulation without generating hydraulic walls slows the rate of sludge digestion.

- This strategy keeps the number of circulators to a minimum.

- INTERMEDIATE DIGESTION

- 270° surface circulation is directional. When the flow feeds from one circulator to the next, the top 3ft of the water column is well mixed.

- This makes the surface sweet layer thick to control odors in higher-concentration, sludge holding ponds.

- RAPID DIGESTION

- 360° circulators are placed in close proximity to the adjacent circulator.

- Hydraulic walls (red dashed lines) carry substrate to the granules and force feed them.

- This is used when ammonia reduction requirements demand rapid sludge digestion (a source of entombed ammonia, released as it is digested).

About the author: Chip Bettle is Co-Inventor & Executive Vice President of Engineering for Absolute Aeration, LLC, Greeley, Colorado, USA. Chip is a chemical engineer who utilizes his unique perspective, straddling both science and engineering, to lead Absolute Aeration in process development. Chip designs complex, low cost solutions to meet regulated discharge requirements. As an inventor he has over 35 approved US patents.

For further information, contact Brandi Waters, Absolute Aeration Customer Service Manager at (386) 233.5074 or email: brandi@bluefrogsystem.net.