ISA: Swagelok introduces new tube fitting

Swagelok's new back-ferrule fitting handles the burst strength of advanced alloy high-pressure tubing while providing an improved grip and seal. It even installs easily.

Swagelok's new back-ferrule fitting handles the burst strength of advanced alloy high-pressure tubing while providing an improved grip and seal. It even installs easily.

By Alan S. Brown

Managing Editor, Chemical Online

Contents:

Product line

Two-ferrule designs

New back ferrule designs

Design

Swagelok Co. (Solon, OH), which made its name 53 years ago with leak-proof tube fittings, chose ISA to introduce a new back-ferrule fitting.

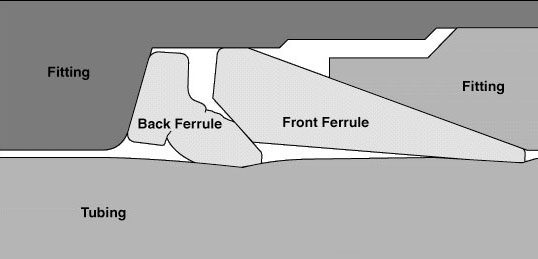

The patented fitting's back ferrule deforms during installation. This increases the grip of the fitting on the tube, creating a better seal and reducing the possibility of improper installation and leakage.

"Our challenge in developing the new Swagelok tube fitting was to maintain or even further reduce installation time and effort, improve performance and maintain compatibility with our original tube fitting," says Swagelok market specialist Mike Valentine.

"What we've come up with is an extremely robust, easy-to-install, and consistently reliable tube fitting, which also is applicable to new alloys used in modern industrial fluid system applications."

Product line

According to industrial market communications leader Robert Fleig, the technology was originally developed for super duplex steel, a stronger, more corrosion-resistant duplex stainless steel alloy.

Like many other advanced alloys, Super Duplex is difficult to deform. This makes it difficult to ensure a proper fit and seal. The back- ferrule design ensures a better seal while preserving the same 1¼-turn installation and installation gages as the original Swagelok tube fitting.

At ISA, Swagelok announced that it would use the same approach for a broader line of 316 stainless steel fittings. The new line is available in 0.25-in., 0.375-in., 0.5-in., 6-mm, 8-mm, 10-mm, and 12-mm fittings. The company plans to manufacture larger sizes in the future.

Two-ferrule designs

Swagelok's patented back-ferrule design efficiently absorbs and redirects installation torque, helping to ensure more predictable gas- tight sealing and remakes. The back ferrule design also offers excellent vibration endurance through greater isolation and support for the tube behind the point of grip.

The New Swagelok Tube Fitting can replace (and is compatible with) the original Swagelok(r) Tube Fitting and uses the same 1-1/4-turn installation requirements and installation gages.

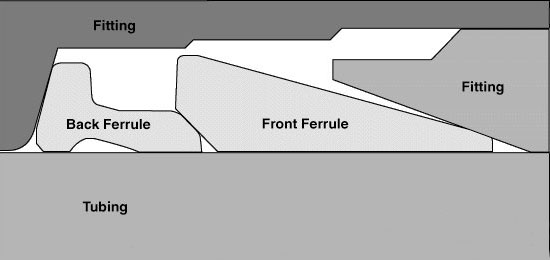

The original Swagelok fitting uses to ferrules. As the fitting body tightens on the ferrules, they lock the fitting into place while choking off any gaps between the tube and fitting nut.

To provide consistent, leak-tight fluid connections, says Swagelok, a two-ferrule tube fitting must:

- Install easily because improper installation and tightening are the leading causes of leakage.

- Handle significant variability in tubing hardness, ovality, wall thickness, and surface finish.

- Provide a consistent feel (measurable as torque required for makeup) because installers often rely on feel as well as instructions to ensure a proper fit.

New back-ferrule designs

In addition to meeting all the requirements of a two-ferrule fitting, Swagelok's new fitting provides additional benefits. It:

- Comes with a larger target area, or sweet spot. This makes it easier for installers to achieve correct pull-up and leak-free performance.

- Has the ability to handle harsher, more corrosive environments.

- Provides greater pressure ratings, durability, and hardness when used with high-alloy tubing and components.

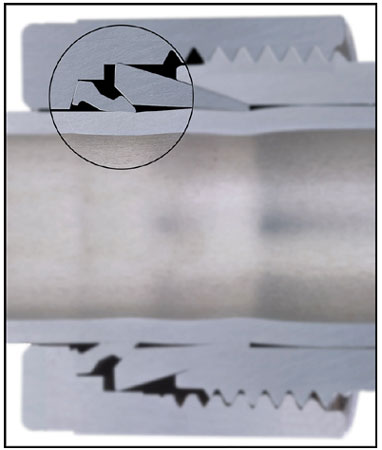

The back ferrule's hinging action translates forward motion into radial swaging of the tube, yet requires less torque. The improved radial colleting action of the back ferrule (to the left of the swage point) isolates and protects the swaged area. It also prevents the exposed vibration stress riser typical of bite-type fittings.

Design

It took Swagelok several years to develop the design. It was originally intended for a company that wanted to use corrosion-resistant super duplex steel fittings. Along the way, Swagelok received two US patents, one in 1999 for its ferrule geometry and one in 2000 for its ferrule surface hardening technique.

Swagelok tested the system with tubing made from super duplex Sandvik SAF 2507. This extremely hard, corrosion-resistant alloy is often specified in offshore oil rigs and other chloride-containing environments.

SAF 2507 tubing often runs at very high pressures. Conventional 316 stainless tube connections simply cannot take the pressure. When made of SAF 2507, Swagelok's new fitting can.

Swagelok lists several other benefits of the new fitting:

- Wider targets. The back-ferrule design not only seals the front ferrule, but delivers greater swaging and gripping action throughout the pull-up process. This decreases the chance of improper installation.

- Improved gas-tight seal. The back ferrule consistently delivers steady force to seal the front ferrule on a wide variety of tubing. The shape of the rear ferrule hinge also absorbs excessive torque. This makes it harder to over-drive the front ferrule. The design ensures a gas-tight seal both initially and throughout repeated remakes.

- Improved vibration fatigue resistance. The back-ferrule design provides more consistent radial colleting action. This protects the swaged area of the tube more effectively from system vibration and fatigue.

- Enhanced performance on commercial tubing. Stainless steel tubing manufacturers do not always run their processes to determine the rupture pressure of a tube at the minimum required material strength values cited by ASTM. Often, tubes have significantly higher burst pressures than minimum standards require. The new Swagelok fitting is robust enough to perform with stronger tubing.

- Compatibility. The new Swagelok tube fitting pulls up using the same 1¼-turn procedure and the same installation gages as the original Swagelok tube fitting. Installers will notice a more consistent feel, including a more consistent range of torque on every pull-up.

For more information: Mike Valentine, Market Specialist, Swagelok Co., 31400 Aurora Rd., Solon, OH 44139-2764. Phone: 440-349- 5934. Fax: 440-349-5806.