Crystalline Silica: The Deadly Dust

Crystalline silica has been linked to several medical conditions and even death to workers exposed to the dust. Exposure to respirable crystalline silica is a health concern for both the construction and plant personnel. In the utility sector, every time a worker has to cut concrete or sandblasts rusting components, they could be exposing themselves to silica dust. This article will shed some light on the exposure possibilities for the wastewater and drinking water professions and how to protect yourself from this deadly dust.

The Issue

Respirable crystalline silica dust is a very small particle of hazardous dust that is linked to lung cancer, silicosis, chronic obstructive pulmonary disease, and kidney disease if breathed into the body. The source of the silica dust is from drilling, crushing, cutting, or grinding rocks such as quartz (the most common surface material by volume to make up the earth’s crust). However, silica can be found in brick, mortar, concrete, slate, granite, tile, sandblasting sand, and filter media. Therefore, it is an abundance mineral that can be a source for illness if the worker isn’t away of protection measure.

Silicosis is a lung disease that is related to silica exposure for workers that have chronic exposure or even acute exposures at a very high level of silica. Workers that develop silicosis have such lung damage that they experience shortness of breath, occasional bluish skin at the ear lobes or lips, chronic fatigue, and loss of appetite.

Regulations

The Occupational Safety and Health Administration (OSHA) has revised its silica standard to reflect the current research which showed the previous standard wasn’t protective enough for workers. The new regulation is expressed in the amount of silica that a worker can be exposed over an 8-hour time weighted average (TWA). This limit is called the permissible exposure limit (PEL) and it has been lowered to 50 micrograms of respirable crystalline silica per cubic meter of air (μg/m3). At the 25 μg/m3 averaged over an 8-hour day level, the employer must take action to reduce the exposure to the worker.

Many industries will be affected by this change including the utility sector, because of the nature of cutting concrete, replacing media sand, and sandblasting activities. In the new construction standard, OSHA has identified 18 tasks that would need specified exposure control methods. The tasks are as follows:

- Stationary masonry saws

- Handheld power saws

- Handheld power saws for fiber cement board

- Walk-behind saws

- Drivable saws

- Rig-mounted core saws or drills

- Handheld and stand-mounted drills

- Dowel drilling rigs for concrete

- Vehicle-mounted drilling rigs for rock and concrete

- Jackhammers and handheld powered chipping tools

- Handheld grinders for mortar removal (tuckpointing)

- Handheld grinders for other than mortar removal

- Walk-behind milling machines and floor grinders

- Small drivable milling machines

- Large drivable milling machines

- Crushing machines

- Heavy equipment and utility vehicles to abrade or fracture silica materials

- Heavy equipment and utility vehicles for grading and excavating

Many of these tasks are done routinely for the utility sector, which places the workers at risk of high concentrations of silica dust exposures.

Exposure Control Options

Controlling exposures to all hazards are done through a three-prong attack:

- Engineering Controls

- Machine guards

- Wet cutting methods

- Soundproofing

- Etc.

- Administrative Controls

- Policies and procedures

- Following O&M manuals

- Conducting job hazard analysis (JHA)

- Etc.

- Personal Protective Equipment (PPE)

- Hand protection

- Eye and face protection

- Respiratory protection

- Etc.

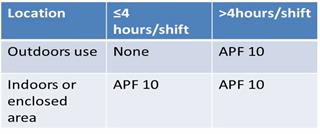

OSHA gives a table of activities with a reference to how to protect yourself from silica exposure. Some activities can be controlled through engineering and administrative controls, but a few have additional requirements for respiratory protection. Each of the tasks with respiratory protection requirements provide the assigned protection factor (APF) of the respirator to be used in the given time exposure.

Jackhammers And Handheld Powered Chipping Tools

An important point for using the engineering exposure control options is to use the equipment as per the manufacturer recommendation, keep the equipment well maintained, and train the operator as to the safe use of the equipment.

If respiratory protection is needed, then the employer should have a written respiratory program, training, and a fit testing system. Utilities under a state OSHA program must provide those elements of a PPE respiratory program as noted above or be subject to a citation.

For the plant staff that use silica sand for media or sandblasting activities, they should be trained as to the dangers of silica sand and exposure. Also, substitute material should be used when possible, such as using walnut shells for sandblasting and not silica sand. If the sand media for filtration is being “blown in” by tanker trucks, then minimize the exposure to other plant personnel with warning signs and wetting airborne particles surrounding areas with service water.

Written Exposure Control Plan And Medical Evaluations

Another requirement in this standard is to have a written exposure control plan which includes the following as a minimum:

- Description of the tasks in the workplace involving exposure to silica

- Description of engineering controls, work practices, and respiratory protection for each task

- Description of housekeeping measures

- Description of procedures used to restrict access to work areas when necessary due to silica exposure

- Annual review of plan for effectiveness and update the plan when necessary

- Written plan must be readily available to each employee covered by the section, their designated representative, the assistant secretary, and the director

Medical evaluation is another requirement for workers who have to wear respirators under the standard for 30 or more days a year. The examinations must be offered every three years and must contain tests for pulmonary functions, chest x-ray, and a physical exam. After the exam, the worker will get a report detailing their health and the employer will receive a medical opinion as per the limitations, if any, to the worker as a result of the exam.

Effective dates for the new ruling for OSHA compliance are:

Construction

- June 23, 2016 – Regulations becomes effective

- June 23, 2017 – Employers must comply with requirements

- June 23, 2018 – Compliance with methods of sample analysis are required

General Industry

- June 23, 2016 – Regulation becomes effective

- June 23, 2018 – Compliance with methods of sample analysis is required

- June 23, 2018 – Engineering controls begin for workers with a PEL for 30 or more days per year

- June 23, 2020 – Exposures at or above action level for 30 days or more per year

Though silica sand in the respirable state can be very dangerous for the workers, it is controllable by engineering, administrative, and PPE. In some cases, the exposure to this dust can be eliminated by substitution methods. However, the utility must protect its workers from this known hazard through the methods outlined in this article and the OSHA standard.