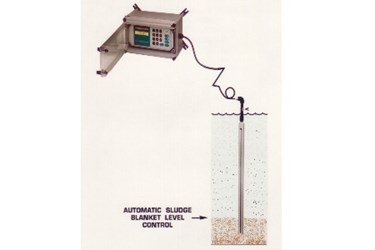

Automatic Sludge Blanket Level Detector: Measure, Monitor & Control Interface Levels

The Automatic Sludge Blanket Level Detector from Markland Specialty Engineering helps monitor and control interface levels, and automate biosolids removal, in clarifiers and settlement tanks when treating raw, incoming process water or wastewater.

It uses high-intensity infrared light to measure levels of primary & secondary sludge, backwash sludge from sand/membrane filters, resin beds in intake water softeners, settled mud levels in tanks and settled fly ash from scrubbers.

It allows users to program de-sludge pumps to operate only when necessary, preventing carryover, optimizing feed density for improved filter press/centrifuge/digester performance, bettering outflow for reuse. In addition, in DAF units, it can adjust surface skimmer speeds to match variations in the thickness of the floating sludge layer; in SBRs, it can control the decant valve to minimize cycle times. Eliminating unnecessary pumping reduces wear-and-tear on pumps, downtime for maintenance, and energy usage.

Its slim profile and use of high-intensity infrared light to measure both sludge bed and overlying cloud layer make it well suited for obstructed or constricted areas; for example, the curved walls of lamellas do not affect readings. No calibration is required. A wireless data link is available.

Source: Markland Specialty Engineering Ltd.