A Treatment Technology For All Occasions

By Kevin Westerling,

@KevinOnWater

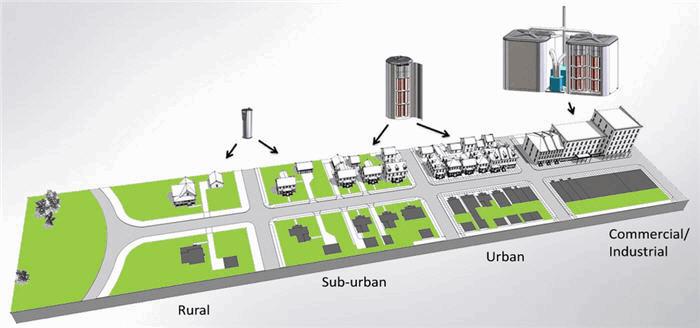

There are a lot of technology startups in the water space vying for attention, including a good bit in the New England area alone, but one Massachusetts company and its potentially "disruptive innovation" stands apart — or at least caught my attention. Aquaback's Distillation Recycling Module (DRM) is intriguing for the claim that it can convert any water source, however dirty, into fresh water that can meet almost any need. It can be used as a decentralized solution for industrial reuse, onsite as a point-of-entry or point-of-use drinking water solution, or within a large municipal plant serving millions of gallons per day. A standalone, physical process that requires no pretreatment, chemicals, or additional equipment, it’s less expensive to purchase and operate than competing technologies, according to Aquaback.

These claims are lofty and unsubstantiated in the field, but that is not to say they’re untrue. Unfortunately, startup companies typically can’t provide the comfort of proven efficacy by way of real-world installations so relied upon by water professionals. However, current and pending water crises — lead contamination in Flint, MI, for example — may increase the demand and hasten the adoption rate for new solutions when others fail or are too expensive.

“While the state and the federal governments debate the merits of one approach over the other, time is passing by and suffering for the citizens of Flint continues,” Aquaback’s Anil Shanbhag conveyed. “It’s our understanding that any solution — whether it’s fixing the pipes that transport the water or using other available technologies — will be costly, will not be as comprehensive, and will take time.”

By contrast, Shanbhag says the DRM can be installed immediately (“out of the box”) at a local school, daycare, church, etc. and therefore bypass the contaminated pipes and associated infrastructure. Or, if the distribution system is up to par, it can be integrated into the existing infrastructure. Wherever it’s set up, the system will remove all contaminants in the range of 10,000 ppm or less to 99.99 percent purity (cleaner than rainwater before it hits the ground).

Shanbhag said he has reached out to public agencies and the private sector in Flint “to explore how we can assist in addressing this great human tragedy.” In the meantime, Aquaback is planning to conduct field trials in the near term to prove what has thus far only been demonstrated through extensive testing in the lab. On an apparent fast track, Shanbhag expects the company to be ready for full-scale manufacturing in the third quarter of 2017.

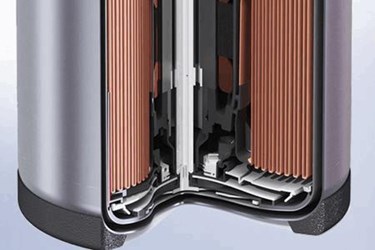

The Distillation Recycling Module can be scaled to suit small or large operations.

Another major crisis that the DRM can help solve is water scarcity, which can be mitigated through municipal or industrial reuse. The latter is the lower-hanging fruit, as it does not involve drinking water nor require the approvals (financial, public, regulatory, etc.) necessary for municipal potable reuse. Among the better candidates is the oil and gas (O&G) industry, often criticized for its water use and wastewater (or “produced water”) disposal. The DRM can take produced water with constituents in excess of 100,000 ppm and make it suitable for reuse.

While the O&G industry and other companies are showing greater interest in corporate social responsibility, cost-effectiveness will continue to be the main consideration for businesses evaluating closed-loop water schemes. The DRM is said to keep costs down through low energy use (99.3 percent of the energy is recycled) and low maintenance requirements (few moving parts, no consumables). It also invites implementation with simplicity: it’s a plug-and-play module that doesn’t require a highly-skilled technician to operate. But for those who are technically inclined, or just curious, here’s how vapor compression distillation works.

According to Shanbhag, the process overcomes the three classic faults associated with distillation-based water treatment: high energy usage, scaling on the evaporator surface, and aerosol spray that could contaminate the treated water.

Is it the cure-all that’s promised? There are still some hurdles to clear, namely regulatory and volume manufacturing, but I’ll root for any technology with the chance to improve water quality and security for more people. It would be a welcome “disruption” indeed.